L.L.Bean

Production Artist and Creative Systems - January 2023 to present

Digital Production Artist/Creative Systems

Process images for web product display pages for various launches.

Provide QA and process requests for product photography

Organize and attribute images on L.L.Bean’s Digital Asset Management system, MediaBank.

Source, edit, and upload images for Google Performance Max Advertising.

Curate and manage image repositories for wholesale partners’ photo asset needs.

Test AI products to determine capabilities for future image generation/retouching.

Provide training for Google Performance Max, Wholesale, and L.L.Bean’s Asset Management System.

Provide support for Digital Asset Management System and wholesale initiatives.

Print Production Artist

Used Adobe InDesign to build catalog layouts based on business and designer specifications.

Media Production Coordinator - August to January, 2023

Used Digital Asset Management System to organize product samples/digital assets and generate reports.

Worked with Art Directors to ensure successful media shoots.

Prepared props/products for shoots on/off set.

Creative Systems Intern - May to August, 2022

Helped create a proposal for wholesale expansion based on audit.

Redesigned Intern and DEI webpages.

Georgetown Pottery

Potter and Multimedia Specialist - January 2014 to May 2023

Created molds for slipcasting.

Helped design pottery mold for a new clock mold.

Poured molds for over a hundred items daily.

Prepared pots for glazing

During the pandemic when the store was closed, I filmed product videos which sold over 120 unique pieces in one month.

Performed electrical wiring for lamps.

Cleaned and organized products

Driftwood Mug

Below is my process for creating a mug out a piece of driftwood I found on a beach. Due to the details in the driftwood, I had to build a 3-piece mold for the body with a separate 2-piece mold for the handle.

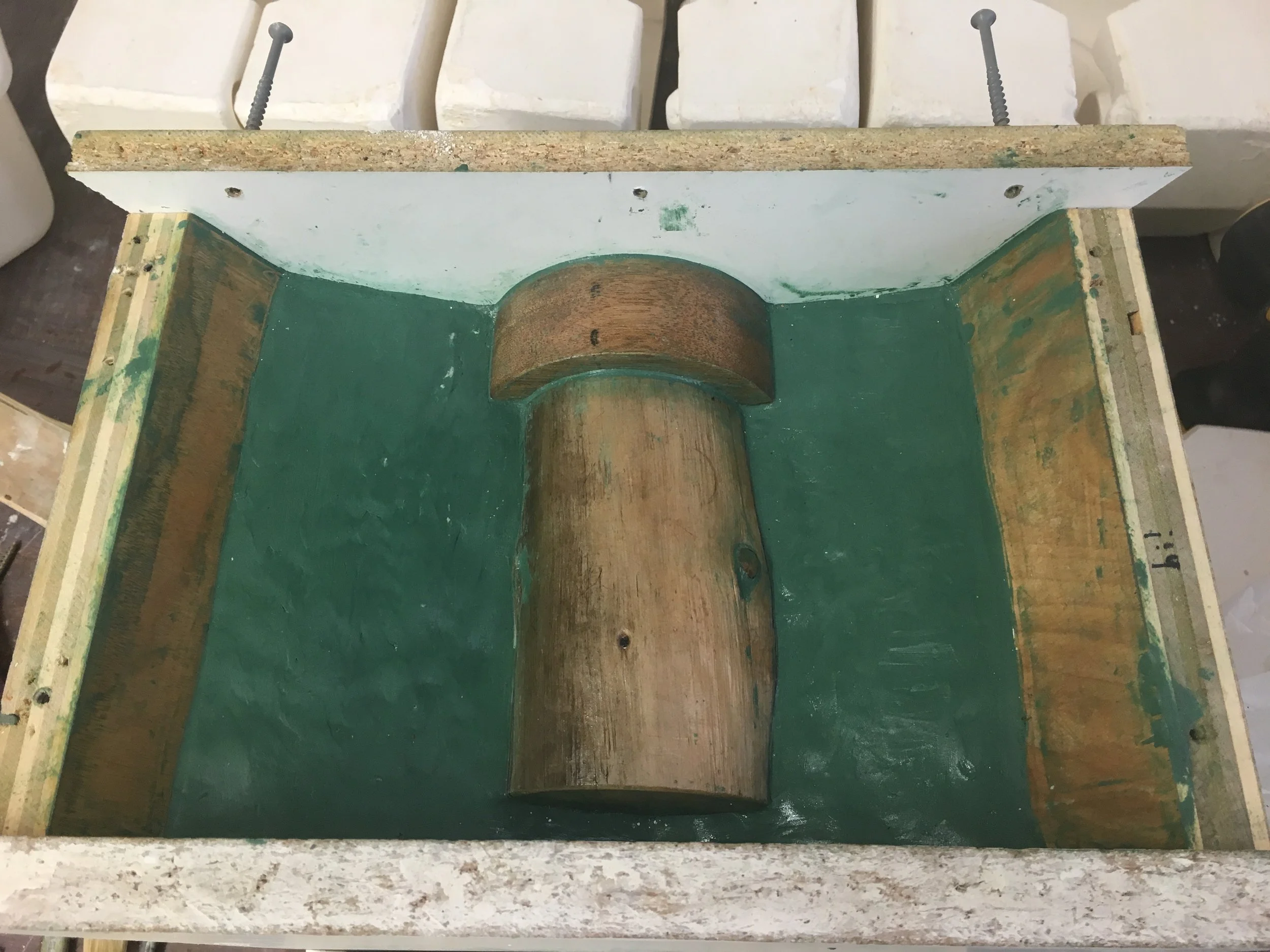

The first step was creating a frame to hold the 3-piece mold.

2/3 of the mold are complete!

Now the mold is filled with wet clay called slip that dries around the plaster edges first

Partitioning the mug with clay to pour the first third of the plaster mold.

After reassembling the frame with the two plaster mold pieces in place, I pour the final third.

I pour out the excess clay and am left with the mug body!

After the plaster dried in the first third. I flipped the mug to pour the second third.

Now the mold is complete and ready for slipcasting!

Now the seams must be trimmed and the handle added on.

This is a close up of the handle mold in progress

Now the first half of the mold is ready to pour!

Plaster is poured into the first half.

The mold is flipped after the first half is dry and now it is ready for the second plaster pour!

Here are both halves.

Wet clay is poured into the hole in the top (pour gate), and the handle is extracted and bent.

Now the handle is ready to attach to the mug.

Here is the mug after trimming

Now the the mug is glazed. I used a black glaze and lightly sanded the mug. This keeps the black in the details of the mug such as the wood grain and knots, but leaves the rest white.

After firing in a kiln the mug is complete!

The black glaze brings out the wood grains.

Each mug has a different color on the inside.

Scouting - 2007 to 2017

My journey to the rank of Eagle Scout in Troop 648 has taught me many things from leadership to lighting a fire with steel wool and a battery. Some of my favorite memories in scouting came from my time as a Troop Guide helping cub scouts transition into the troop. For my eagle project, I cleaned up and added trail markers to a half-mile public trail. Through fundraising and a generous donation from Hammond Lumber, I was able to build 10 bog bridges on muddy areas of the trail which are in good condition even today!